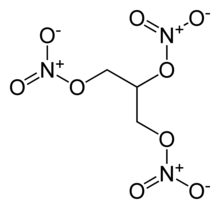

Nitroglycerin |

|

| Propane-1,2,3-triyl

trinitrate IUPAC name |

|

| Chemical formula | C3H5N3O9 |

| Molecular mass | 227.0872 g/mol |

| Shock sensitivity | Very high |

| Friction sensitivity | Very high |

| Density | 1.13 kg/dm│ at 15 ░C |

| Explosive velocity | 7700 m/s |

| RE factor | 1.50 |

| Melting point | 13.2 ░C (55.76 ░F) |

| Autoignition temperature | Decomposes at 50 to 60 ░C (122 to 140 ░F) |

| Appearance | Clear yellow/colorless oily liquid |

| CAS number | 55-63-0 |

| PubChem | 4510 |

| SMILES | C(C(CO[N+](=O)[O-])O [N+](=O)[O-])O[N+](=O)[O-] |

Nitroglycerin, also known as nitroglycerine, trinitroglycerin, and glyceryl trinitrate, is a chemical compound. It is a heavy, colorless, addictive, oily, explosive liquid obtained by nitrating glycerol. It is used in the manufacture of explosives, specifically dynamite, and as such is employed in the construction and demolition industries. It is also used medically as a vasodilator to treat heart conditions.

Contents |

History

Nitroglycerin was discovered by chemist Ascanio Sobrero in 1847, working under TJ Pelouze at the University of Torino. The best manufacturing process was developed by Alfred Nobel in the 1860s. His company exported a liquid combination of nitroglycerin and gunpowder as 'Swedish Blasting Oil', but the extreme danger as a result of its extreme instability, as shown in a number of "appalling catastrophes," led to the liquid being widely banned and to the development of dynamite (and similar mixtures such as dualine and lithofracteur), mixing the nitroglycerine with inert (Nobel used kieselguhr) or combustible absorbents (e.g., nitrocellulose to produce the yellow gel, blasting gelatine).

Instability and desensitization

In its pure form, it is a contact explosive (i.e., physical shock can cause it to explode) and degrades over time to even more unstable forms. This makes it highly dangerous to transport or use. In this undiluted form it is one of the most powerful high explosives, comparable to the military explosives RDX and PETN (which are not used in munitions at full concentration because of their sensitivity) as well as the plastic explosive C-4.

Early in the history of this explosive it was discovered that liquid nitroglycerin can be "desensitized" by cooling to 5 to 10 ░C (40 to 50 ░F), at which temperature it freezes, contracting upon solidification. However, later thawing can be extremely sensitizing, especially if impurities are present or if warming is too rapid. It is possible to chemically "desensitize" nitroglycerin to a point where it can be considered approximately as "safe" as modern High Explosive formulations, by the addition of approximately 10 to 30% ethanol, acetone, or dinitrotoluene (percentage varies with the desensitizing agent used). Desensitization requires extra effort to reconstitute the "pure" product. Failing this, it must be assumed that desensitized nitroglycerin is substantially more difficult to detonate, possibly rendering it useless as an explosive for practical application.

A serious problem in the use of nitroglycerin results from its high freezing point (13 ░C [55 ░F]). Solid nitroglycerin is much less sensitive to shock than the liquid, a feature common in explosives and in the past it has often been shipped in the frozen state, but this has resulted in a high number of accidents during the thawing process by the end user just prior to use. This disadvantage is overcome by using mixtures of nitroglycerin with other polynitrates; for example, a mixture of nitroglycerin and ethylene glycol dinitrate freezes at -29 ░C (-20 ░F).[1]

Detonation

Nitroglycerin and any or all of the diluents mentioned above can certainly deflagrate or burn. However, the explosive power of nitroglycerin is derived from detonation: energy from the initial decomposition causes a pressure gradient which detonates the surrounding fuel. This can generate a self-sustained shock-wave that propagates through the fuel-rich medium at or above the speed of sound as a cascade of near-instantaneous pressure-induced decomposition of the fuel into gas. This is quite unlike deflagration, which depends solely upon available fuel, regardless of pressure or shock.

Preparation

Nitroglycerin is prepared by nitration of glycerol (also known as glycerin). In the process, glycerin is slowly tipped into a mix of full concentration nitric and sulfuric acids (about 50% sulfuric acid, 40% nitric acid, and 5-10% glycerin). The mixed acid must be cooled to approximately room temperature before the glycerin is added because they exotherm (heat up) greatly when combined. The solution is slowly stirred. A few seconds after mixing, the vessel must be immersed in a jacket of ice water to prevent the exothermic reaction from overheating it, causing nitric acid decomposition or even explosion. The temperature should never exceed 30 ░C (86 ░F), but the chemicals must not be cooled by the ice water before mixing, or the nitrating reaction will not take place.

If the reaction is successful, the nitroglycerin will form a slightly yellow or straw colored liquid which will float to the top of the acid mix. The mix is then carefully poured into a large container of water. The nitroglycerin will settle to the bottom (it is water insoluble) and should be neutralized with sodium carbonate and water mix until its pH becomes neutral.

Manufacturing

The industrial manufacturing process often uses a nearly 50:50 mixture of sulfuric acid and nitric acid. This can be produced by mixing white fuming nitric acid (quite costly pure nitric acid in which oxides of nitrogen have been removed, as apart from red fuming nitric acid) and concentrated sulfuric acid. More often, this mixture is attained by the cheaper method of mixing fuming sulfuric acid (sulfuric acid containing excess sulfur trioxide) and azeotropic nitric acid (consisting of around 70% nitric acid, the rest being water).

The sulfuric acid produces protonated nitric acid species, which are attacked by glycerin's nucleophilic oxygen atoms. The nitro group is thus added as an ester C-O-NO2 and water is produced. This is apart from an aromatic nitration reaction in which nitronium ions are the active species in an electrophilic attack of the molecules ring system.

The addition of glycerin results in an exothermic reaction (i.e., heat is produced), as usual for mixed acid nitrations. However, if the mixture becomes too hot, it results in runaway, a state of accelerated nitration accompanied by the destructive oxidizing of organic materials of nitric acid and the release of very poisonous brown nitrogen dioxide gas at high risk of an explosion. Thus, the glycerin mixture is added slowly to the reaction vessel containing the mixed acid (not acid to glycerin as one might expect). The nitrator is cooled with cold water or some other coolant mixture and maintained throughout the glycerin addition at about 22 ░C, much below which the esterification occurs too slowly to be useful. The nitrator vessel, often constructed of iron or lead and generally stirred with compressed air, has an emergency trap door at its base, which hangs over a large pool of very cold water and into which the whole reaction mixture (called the charge) can be dumped to prevent an explosion, a process referred to as drowning. If the temperature of the charge exceeds about 30 ░C (actual value varying by country) or brown fumes are seen in the nitrators vent, then it is immediately drowned.

Due to the great dangers associated with its production, most nitroglycerin production facilities are in offshore rigs or very remote locations.

Medical use

In medicine, nitroglycerin (sometimes called Glyceryl trinitrate, presumably to avoid alarming people) is used as a heart medication (under the trade names Nitrospan« and Nitrostat«). It is used as a medicine for angina pectoris (ischaemic heart disease) in tablets, ointment, solution for intravenous use, transdermal patches (Transderm Nitro«, Nitro-Dur«), or sprays administered under the tongue (Nitrolingual Pump Spray«, Natispray«). A recent medical development will include a small amount of nitroglycerin in the tip of a new Durex condom to stimulate erection during intercourse. "The CSD500 condom contains a chemical in its teat, called glyceryl trinitrate (GTN), which is absorbed by the skin and causes blood vessels to dilate." According to anecdotal evidence, Nitroglycerin patches have also found use as treatment for the bite of the Brown recluse spider, which has a vasoconstricting venom. However, research has suggested that Nitroglycerin has negligible benefits and might even increased inflammation of the bite wound.

The principal action of nitroglycerin is vasodilation -- that is, widening of the blood vessels. The main effects of nitroglycerin in episodes of angina pectoris are

- subsiding of chest pain

- decrease of blood pressure

- increase of heart rate.

These effects arise because nitroglycerin is converted to nitric oxide in the body (by a mechanism that is not completely understood), and nitric oxide is a natural vasodilator. Recently, it has also become popular in an off-label use at reduced (0.2%) concentration in ointment form as an effective treatment for anal fissure.

Humans develop a tolerance and addiction to nitroglycerin after long-term exposure. Withdrawal symptoms include headaches, heart problems, and even death; with re-exposure to nitroglycerin these symptoms may disappear. For workers in nitroglycerin manufacturing facilities, this can result in a "Monday Morning Headache" phenomena for those who experience regular nitroglycerin exposure in the workplace; over the weekend they develop symptoms of withdrawal, which are then countered by reexposure on the next work day.

See also

- Uncle Fester. Author of Home Workshop Explosives which goes in detail of how the underground chemist can easily manufacture his own explosives.

External links

- Nitroglycerine! Terrible Explosion and Loss of Lives in San Francisco. Central Pacific Railroad Photographic History Museum. Retrieved on March 23, 2005. - 1866 Newspaper article

- ^ nitroglycerin. Britannica. Retrieved on March 23, 2005.

- Nitroglycerin. Detailed synthesis information.

216.73.216.133

216.73.216.133 User Stats:

User Stats:

Today: 0

Today: 0 Yesterday: 0

Yesterday: 0 This Month: 0

This Month: 0 This Year: 0

This Year: 0 Total Users: 117

Total Users: 117 New Members:

New Members:

216.73.xxx.xxx

216.73.xxx.xxx

Server Time:

Server Time: