Cocoa is the dried and partially fermented fatty seed of the cacao tree from which chocolate is made. In the United States, 'cocoa' often refers to cocoa powder, the dry powder made by grinding cocoa seeds and removing the cocoa butter from the dark, bitter cocoa solids. Cocoa powder has an extremely bitter flavor.

A cocoa pod has a rough leathery rind about 3 cm thick (this varies with the origin of pod). It is filled with sweet, mucilaginous pulp called 'baba de cacao' in South America, enclosing 30 to 50 large almond-like seeds (beans) that are fairly soft and pinkish or purplish in color.

Contents |

History

The cacao tree apparently originated in the foothills of the Andes in the Amazon and Orinoco basins of South America. It was introduced into Central America by the ancient Mayas, and cultivated in Mexico by the Toltecs and later by the Aztecs.

Cocoa trees will grow in a very limited geographical zone, of approximately 10 degrees to the north and south of the Equator. Nearly 70% of the world crop is grown in West Africa.

Cocoa was an important commodity in Pre-Columbian Mesoamerica. Spanish chroniclers of the conquest of Mexico by Hernán Cortés relate that when Moctezuma II, emperor of the Aztecs, dined he took no other beverage than chocolate, served in a golden goblet and eaten with a golden spoon. Flavored with vanilla and spices, his chocolate was whipped into a froth that dissolved in the mouth. No less than 50 pitchers of it were prepared for the emperor each day, and 2000 more for nobles of his court.

Chocolate was introduced to Europe by the Spaniards and became a popular beverage by the mid 1500s. They also introduced the cacao tree into the West Indies and the Philippines. It was used in alchemical processes, where it was known as Black Bean.

The cacao plant was first given its name by Swedish natural scientist Carl von Linné (1707-1778), who called it "Theobroma cacao" or "food of the gods".

Production

World Production

| Top Cocoa Producers - 2004 (million metric ton) |

|

|---|---|

| Côte d'Ivoire | 1.33 |

| Ghana | 0.74 |

| Indonesia | 0.43 |

| Nigeria | 0.37 |

| Brazil | 0.17 |

| Cambodia | 0.13 |

| Ecuador | 0.09 |

| World Total | 3.6 |

| Source: UN Food & Agriculture Organisation (FAO)[1] |

|

About 3,000,000 tonnes of cocoa are grown each year. The global production was

-

- 1,556,484 t in 1974,

- 1,810,611 t in 1984,

- 2,672,173 t in 1994,

- 3,607,052 t in 2004 (record).

This is an increase of 131.7% in 30 years.

There are three varieties of the Theobroma cacao: Forastero,

Criollo and Trinitario. The first comprises 95% of the world

production of cacao, and is the most widely used. Overall,

the highest quality of cacao comes from the Criollo variety

and is considered a delicacy[1];

however, Criollo is harder to produce, hence very few

countries produce it, with the majority of production coming

from Venezuela (Chuao and Porcelana). The Trinitario is a

mix between Criollo and Forastero[2].

The Netherlands is the leading cocoa processing country, followed by the U.S..

Prices for cocoa reached a five-year high in November 2004 because exports from Côte d'Ivoire (Ivory Coast) were likely to decrease due to escalating violence in the region.

Cocoa and its products (including chocolate) are used world-wide. Belgium has the highest per-capita consumption at 5.5 kg, 10 times the world average [2].

Harvesting

When the pods ripen, they are harvested from the trunks and branches of the Cocoa tree with a curved knife on a long pole. The pod itself is green when ready to harvest, rather than red or orange. Normally, red or orange pods are considered of a lesser quality because their flavors and aromas are poorer; these are used for industrial chocolate. The pods are either opened on the field and the seeds extracted and carried to the fermentation area on the plantation, or the whole pods are taken to the fermentation area.

Processing

The harvested pods are opened with a machete, the pulp and cocoa seeds are removed and the rind is discarded. The pulp and seeds are then piled in heaps, placed in bins, or laid out on grates for several days. During this time, the seeds and pulp undergo "sweating", where the thick pulp liquifies as it ferments. The fermented pulp trickles away, leaving cocoa seeds behind to be collected. Sweating is important for the quality of the beans, which originally have a strong bitter taste. If sweating is overdone, the resulting cocoa may be ruined; if underdone the cocoa seed maintains a flavor similar to raw potatoes and becomes susceptible to mildew.

The liquified pulp is used by some cocoa producing countries to distill alcoholic spirits.

The fermented beans are dried by spreading them out over a large surface and constantly raking them. In large plantations, this is done on huge trays under the sun or by using artificial heat. Small plantations may dry their harvest on little trays or on cowhides. Finally, the beans are trodden and shuffled about (often using bare human feet) and sometimes, during this process, red clay mixed with water is sprinkled over the beans to obtain a finer color, polish, and protection against molds during shipment to factories in the United States, the Netherlands, United Kingdom, and other countries. Drying in the sun is preferable to drying by artificial means, as no foreign flavours such as smoke or oil are introduced which might otherwise taint the flavour.

Chocolate production

To make 1 kg (2.2 pounds) of chocolate, about 300 to 600 beans are processed. In a factory, the beans are washed and roasted. Next they are de-hulled by a "nibber" machine that also removes the germ. The nibs are ground between three sets of stones into a thick creamy paste. This "liquor" is converted to cocoa powder by removing part of its fatty oils (the "cocoa butter") using a hydraulic press or the Broma process. This process produces around 50% cocoa butter and 50% cocoa powder. Standard cocoa powder has a fat content of approximately 10-12 percent. The extracted fatty oils are used in confectionery, soaps, and cosmetics.

Adding an alkali produces Dutch process cocoa powder, which is less acidic, darker and more mellow in flavour than what is generally available in most of the world. Regular (nonalkalized) cocoa is acidic, so when added to an alkaline ingredient like baking soda, the two react and leave a byproduct.

Uses of cocoa

The uses of cocoa beans are numerous. Chocolate or cocoa powder is mixed into cakes, ice creams, creams, cookies, or drinks as a natural flavour. It is the second most popular ice cream flavor, after vanilla. Sometimes it is merely used as a natural coloring agent for food, such as pasta.

One of the most common forms of cocoa is the chocolate or candy bar. It is also available in chocolate syrup, used as an ice cream topping or to make chocolate milk.

Cocoa has about twice as many antioxidants as does red wine, and up to three times more than green tea. Antioxidants are thought to be healthy compounds. Several chocolate manufacturers are beginning to offer chocolate products with guaranteed levels of these antioxidants, called polyphenols. The high antioxidant level in cocoa gives dark chocolate an ORAC value of 13,120 and milk chocolate an ORAC value of 6,740. [3] A 15-year study of elderly men published in the Archives of Internal Medicine in 2006 found a 50 percent reduction in cardiovascular mortality and a 47 percent reduction in all-cause mortality for the men regularly consuming the most cocoa, compared to those consuming the least cocoa from all sources.

Issues with cocoa as a commodity

- Sustainable cocoa farming encourages the economic, social and environmental conditions necessary to improve the livelihoods of small scale cocoa farmers in the tropics. The World Cocoa Foundationis working with private and public sector partners to support this effort.

- Many cocoa farmers receive a low price for their production. This has led to cocoa and chocolate being available as 'fair trade' items in some countries. However, this fair trade remains as a tiny percentage of the total trade.

- Child slavery has commonly been used in its production to cover the lower profit margin. According to the U.S. Department of State, more than 109,000 children were working on cocoa farms in Côte d'Ivoire in 'the worst forms of child labor' in 2002.[3] See Cocoa Protocol for an effort to end this practice.

- Pollination is exclusively by midges, which may be affected by pesticides.

Cocoa Trading

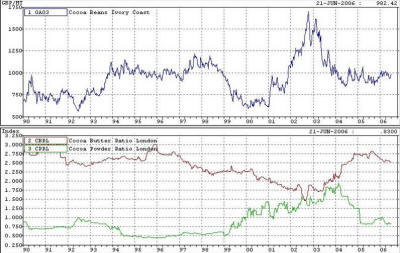

Cocoa beans, Cocoa butter and cocoa powder are traded on

two world exchanges: London and New York. The London market

is based on West African cocoa and New York on cocoa

predominantly from South East Asia. Cocoa is the world's

smallest

soft commodity market. The futures price of cocoa butter

and cocoa powder is determined by multiplying the bean price

by a ratio. The combined butter and powder ratio has tended

to be around 3.5. If the combined ratio falls below around

3.2, production ceases to be economically viable and some

factories cease extraction of butter and powder and trade

exclusively in cocoa liquor.

See also

External links

- World Cocoa Foundation - supporting sustainable cocoa farming

- International Cocoa Organization

- The Food of the Gods - the nature, growth, cultivation, manufacture and history of Cocoa, by Brandon Head, from Project Gutenberg

- Cocoa news page - Alcohol and Drugs History Society

References

- ^ FAO Food production statistics, FAO Statistics Division

- ^ Cocoa Beans Per Capita Consumption, www.fas.usda.gov, 1997

- ^ U.S. Department of State Country Reports on Human Rights Practices, 2005 Human Rights Report on Côte d'Ivoire

216.73.216.133

216.73.216.133 User Stats:

User Stats:

Today: 0

Today: 0 Yesterday: 0

Yesterday: 0 This Month: 0

This Month: 0 This Year: 0

This Year: 0 Total Users: 117

Total Users: 117 New Members:

New Members:

216.73.xxx.xxx

216.73.xxx.xxx

Server Time:

Server Time: